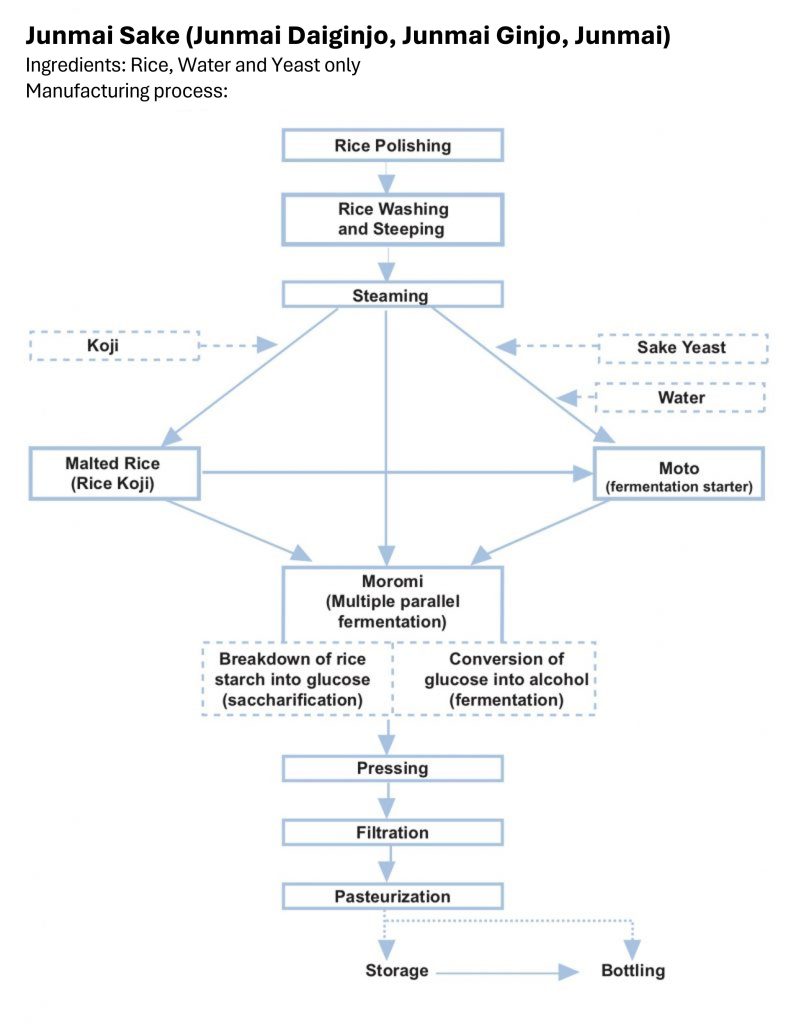

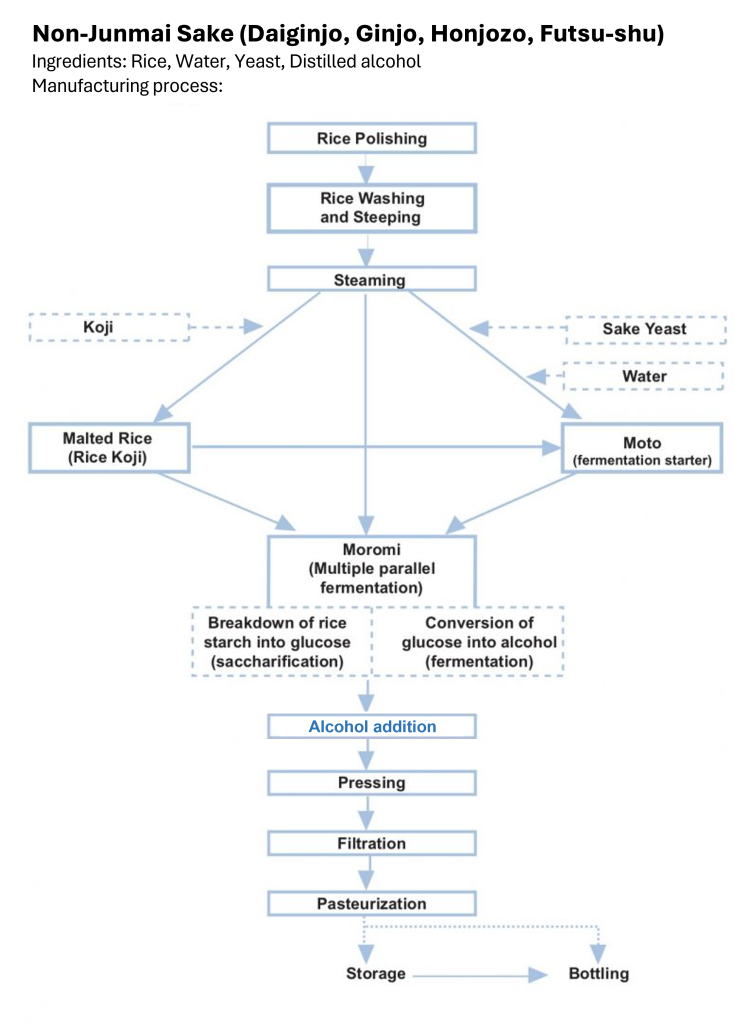

Sake is produced through the fermentation of rice and water, using yeast and koji (aspergillus oryzae) as facilitators. The process has some similarities to other alcohol fermentations such as beer or wine production, but the use of koji-colonized rice in place of either malted grain or sugar-rich fruit adds another dimension to the brewing process. Below we illustrate the basic brewing procedure.

Polishing

Rice is first transferred to a polishing machine which gently polishes off the outer layer of the grains. This exercise is to remove, as much as possible, the exterior layers of the rice grains that contain protein, minerals, fats, and vitamins. These substances or impurities, if not removed, will affect the fermentation process and contribute to off-flavors and muddiness in the finished sake. The percentage amount of rice being polished off will play a very important role in governing the quality of the finished product and also in the grading of sake.

Washing

After the polishing process is completed, the rice is ready for washing. The polished rice has to be washed thoroughly to ensure no rice powder and impurities cling to the surface of the grain before the steeping and steaming process.

Steeping

The purpose is to ensure the rice grains absorb the desired amount of water before steaming.

Steaming

Steaming softens the grains and breaks down the starch molecules, facilitating for the growth of the Koji. The correct firmness is important for the progress of fermentation in the main batch and affects the final taste of the sake.

Koji Making

After the steamed rice is lowered down to a certain temperature, it is transported to the Koji room. Koji spore is an enzyme, which converts the starch in rice into sugar. The rice is then placed and spread symmetrically over wooden trays. The sake master will manually spread the Koji spores uniformly over the rice. This rice is squeezed and pressed by hand repeatedly over regular intervals of the day to ensure an even growth of Koji. When the Koji rice is ready for the next process, it has to be dehydrated for one whole day before reaching proper dryness.

Mixing

When it is dry, the Koji is then placed into water along with the yeast starter. This mixture is known as Moto. During this stage, sugar through the chemical reaction with Koji is converted into alcohol.

Fermentation

The Moto, which is considered the “seed mash”, will be added to additional steamed rice and water inside the fermentation tanks. The temperature and timing for this fermentation process have to be controlled carefully in order to produce sake of premium qualities. The sake mixture of this stage is named Moromi, which is the “final mash”.

Alcohol Addition

Pressing

When the fermentation is completed, the Moromi will be squeezed to release a clear liquid which will then be pasteurized and matured in stainless steel tanks for a period of time before bottling.